Junction Flows Horseshoe Vortex Dynamics

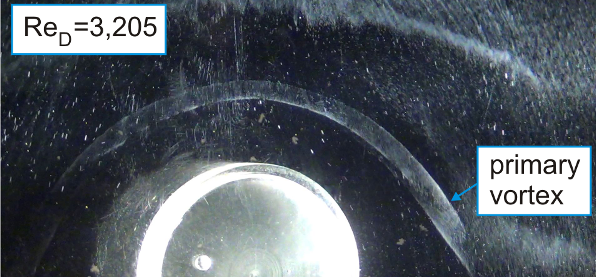

When a boundary layer flow (either laminar or turbulent) encounters an

obstacle projecting from that surface, some distance upstream of the

obstacle the boundary layer separates as a result of the adverse

pressure gradient, and rolls up to form three-dimensional complex

vortices. These vortices have the characteristic shape of a horseshoe,

such that the legs of the vortices extend downstream, to both sides of

the body. Figure below is obtained through hydrogen bubble

visualization and shows the shape of the horseshoe vortex forming

upstream of a cylinder-plate juction.

Figure 1:

Laminar horseshoe vortex forming upstream of the cylinder-plate

junction. Visualization is achieved through hydrogen bubble technique

in our water channel.

Horseshoe vortices form in many real

scenarios, such as at wing-body junctions in airplanes, turbine

blade-hub junctions, cooling flow past computer chips, and so on.

Horseshoe vortices often have large effects on flow properties in the

junction region, such as the local heat transfer, skin friction, and

noise. For example, at the junction of an airplane wing with the

fuselage, formation of horseshoe vortices and associated complex flow

can dramatically impair the performance of the aircraft. It can result

in an increase in local skin friction, noise, and drag. The drag

induced by the wing-fuselage junction is estimated to be 10% of the

total drag in modern civil airplanes. Hence, the design of wing-body

junctions or empennage-fuselage junctions is important for aircraft

makers. In the case of a bridge or pier suport, for instance, owing to

the horseshoe vortices, local skin friction can cause severe erosion at

the junction. Another situation, where horseshoe vortices have dramatic

effects, is a turbine blade-hub junction. In this case, horseshoe

vortices can affect increase the local heat transfer rates and thereby

cause thermal gradients in the blade.

The present investigation consists of two phases:

In

the first phase, the project investigates how the characteristics of

the oncoming bounday layer affects the unsteady dynamics of horseshoe

vortex systems. To this end, an experimental investigation is conducted

involving cylinder-channel floor and cylinder-end plate junctions. By

changing the leading-edge geometry of the endplates and the cylinder

position from the tip of the endplate, effects both laminar and

turbulent aproach flows with various characteristics are studied.

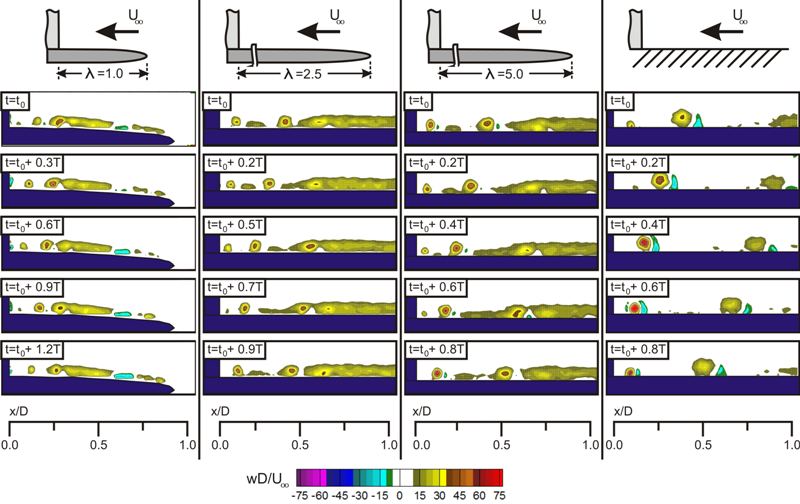

Below, in Figure 2, one excerpt from many of our interesting findings

is given. A journal publications is at the submission stage on this

phase of the investigation. Interested fellows: stay tuned for further

information.

Figure 2:

Iso-contours of vorticity: Snapshots of the junction flow at the

upstream of the symmetry plane are shown for cylinder-endplate junction

in the first three columns and for the cylinder-channel floor junction

in the last column. An increase in the thickness of the laminar

boundary layer results in a gradual decrease in the formation frequency

of horseshoe vortices. This effect can be distinguished visually by the

increasing distance between the primary and secondary horseshoe vortex

in this figure.

In the second phase, to reduce the adverse

effects of the unsteady horseshoe vortex flows, modifications to the

geometry of the wing/body will be examined. The project will

specifically investigate the effects of adding simple flow control

devices, such as fillets, leading edge adjustments, and fairings, on

idealized wing junctions.